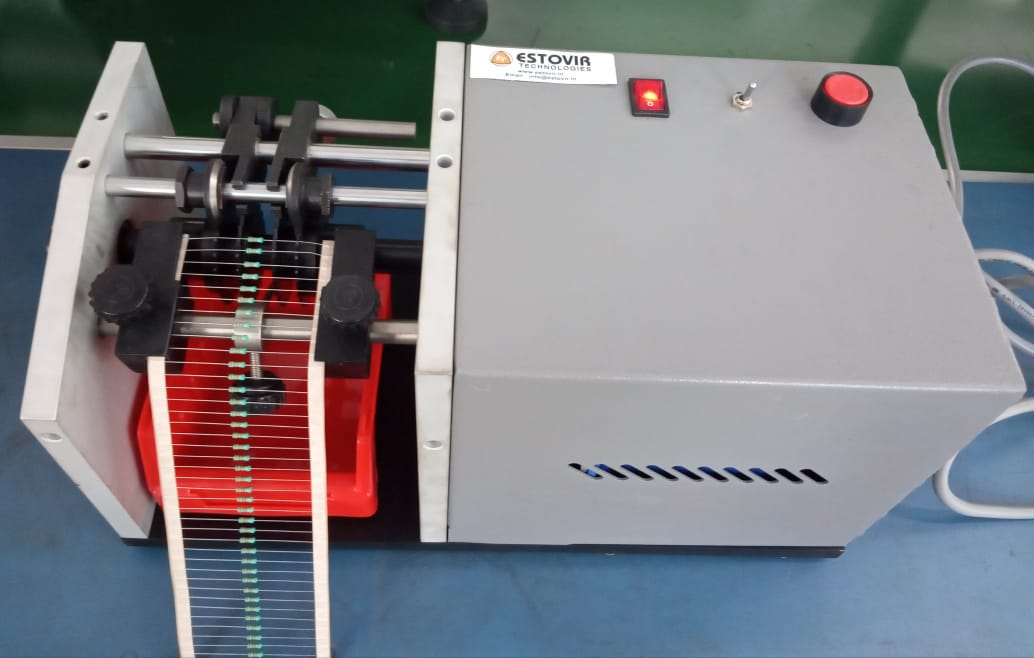

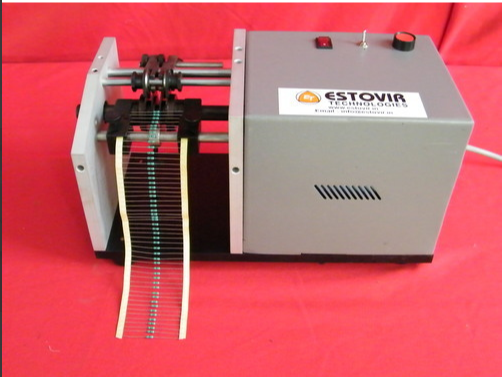

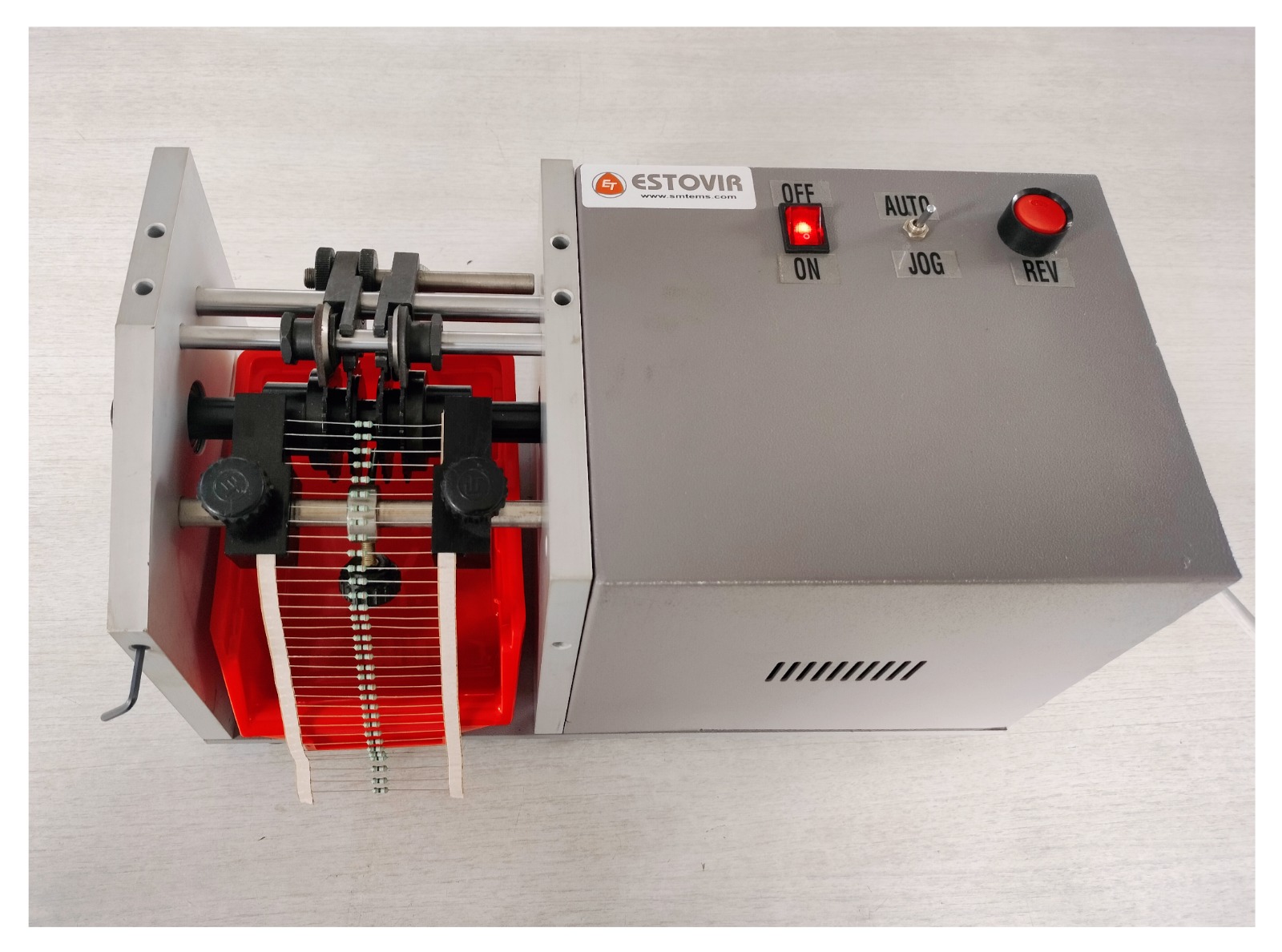

Automatic Cut and Bend Machine (UAP 850 A) by Estovir Technologies

The Automatic Cut and Bend Machine (UAP 850 A) is a high-performance, motorized solution for cutting and bending axial leaded components up to 0.8mm soft wire. Designed to handle components with thicker leads, it delivers accurate output with minimal manual handling. Whether used for power diodes, high-current Zener diodes, or high-wattage resistors, this machine ensures productivity, reliability, and repeatability in demanding manufacturing environments.

Developed by Estovir Technologies, the UAP 850 features a durable design and user-friendly controls. It enables smooth feeding of taped axial components through guide sets and automatically processes them to the required pitch and leg length. The machine’s rugged construction and high-rated motor ensure long-term performance with minimal maintenance.

Key Features:

- Automatic Motorized Operation: Performs cutting and bending automatically for reduced manual workload.

- Supports Thick Lead Components: Handles 1A power diodes, Zener diodes, and high-wattage resistors with ease.

- High-Speed Output: Delivers up to 14,000 components per hour, ideal for high-volume production.

- Easy Pitch and Leg Length Adjustment: Quick setup changes allow fast transitions between component types.

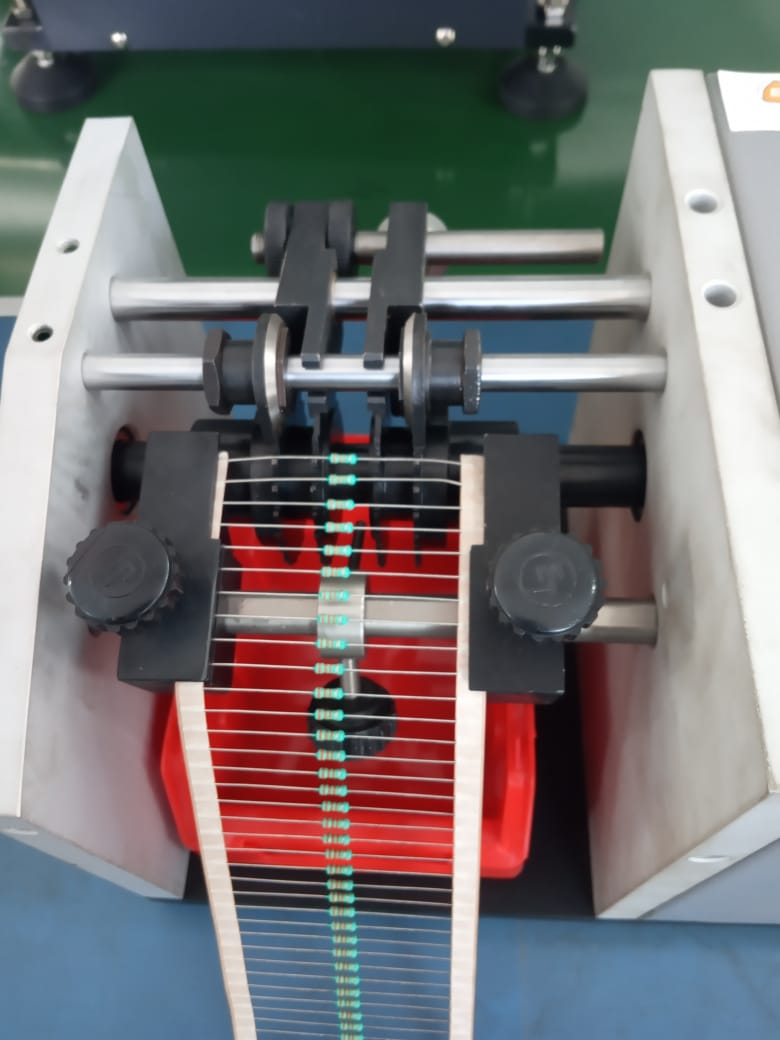

- Heavy-Duty Pickup Wheels: Built with increased thickness for durability and better grip on components.

- Minimal Operator Involvement: Once set, it runs efficiently with limited supervision depending on tape quality.

- Smooth Taped Component Feeding: Comes with guide sets to ensure consistent input from taped axial components.

- Compact and Durable Design: Occupies minimal floor space while delivering robust industrial performance.

Why Choose the UAP 850 A Cut and Bend Machine from Estovir Technologies

- Designed for industrial-grade continuous operation

- Efficient handling up to 0.8mm leads.

- Faster changeovers reduce downtime between batches

- Built for precision, longevity, and consistent output

- Dependable delivery and service support across India

The Automatic Cut and Bend Machine (UAP 850 A) is built to meet the growing demand for speed, accuracy, and minimal labor in electronics component processing. With its rugged design, high-speed capability, and support for 0.8mm axial components, it’s a must-have for any high-volume assembly line.

To further streamline operations, Estovir Technologies offers a complete range of manual and automatic preforming machines to handle different requirements:

- Cut and Bend Machine – Cut and bend of taped radial components up to Dia 0.8mm soft wire.

- Manual: Manual Cut & Bend Machine for Taped Axials – MAP 860 A

- Motorized: Automatic Cut & Bend Machine for Taped Axials – UAP 850 A

- De-Taping Machine – Cutting of taped radial components for tape

- Forming for Taped Axials Vertical – Perfect for vertical forming of axials up to Dia 1.37mm

- Forming for Taped Axials Horizontal– Suitable for horizontal forming of taped axials up to Dia 1.37mm

Each of these machines is engineered for high performance and supported by Estovir’s reliable service and fast delivery